THERMAL CUTTING

Precision plasma / thermal cutting technologies and capacities / Sigma 6 Derbyshire / Services

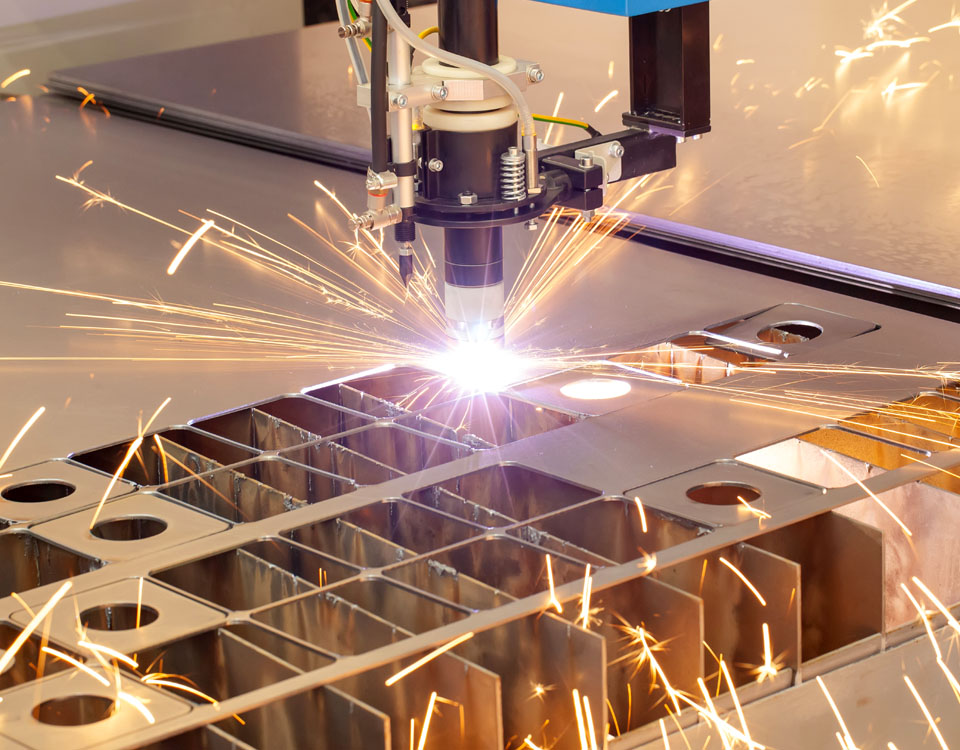

FERROUS & NON FERROUS, HIGH PERFORMANCE PLASMA CUTTING BY THE ESPIRIT VIPER CNC THERMAL CUTTER SYSTEM

ESPIRIT VIPER CNC THERMAL / PLASMA CUTTER

Sigma 6 recently invested in an Esprit Viper CNC thermal cutting system. Designed and manufactured as precision machine tools, Viper machines feature heavy duty floor mounted rails, hardened and ground linear bearings, powerful digital AC drive systems, precision gearboxes, and direct rack and pinion drives for excellent machine performance.

It is the machine of choice for the most demanding applications working up to 24 hours / day.

Cutting width on these flame & plasma profile cutting machines can be specified between 1.5 m and 6.5 m; cutting length is effectively unlimited. Viper machines can be fitted with Hypertherm XPR, HPRXD or conventional plasma cutting systems up to 800 A, or oxy-fuel flame cutting torches for the thicker material ranges.

CNC PROFILE CUTTING

Our CNC Profile Cutting machines are suitable for precision cutting in the most demanding of applications. Range of standard size materials held on stock in-house.

KEY POINTS

- Thermal Cutting Capabilities Include:

260A Plasma Cutting of ferrous and non-ferrous plate material up to 35mm thick. - Oxy-fuel cutting of ferrous plate material up to 125mm thick.

- HyPerformance HPR260XD plasma cutting torch with True-hole technology allowing for greater accuracy of hole cutting in plate material.

- Cutting table capacity 4000mm X 2000mm Improved accuracy and edge finish with little if no fettling required.

MORE

For more information and enquiries on our Thermal and Plasma Cutter capabilities and services, please contact Sigma 6 WRS Ltd.